KÄSSBOHRER

WERELDWIJD

Al meer dan 125 jaar ontwikkelt Kässbohrer voertuigen die de grenzen van techniek verleggen. Onze producten, gebouwd om lang mee te gaan, zijn afgestemd op de behoeften van onze klanten, en helpen hen om hun ambities waar te maken, ongeacht hoe uitdagend hun vereisten zijn. We worden geïnspireerd door onze geschiedenis van innovatie, kijken altijd naar de toekomst, anticiperen op de uitdagingen van morgen en verzekeren dat we daaraan het hoofd kunnen bieden.

Op dit moment heeft Kässbohrer productiefaciliteiten in Goch / Duitsland, Adapazari / Turkije. We zijn trots terug te keren naar onze thuisbasis in Ulm met onze nieuwste productie-, distributie- en servicefaciliteit.

PARTNERSCHAP

ZONDER GRENZEN

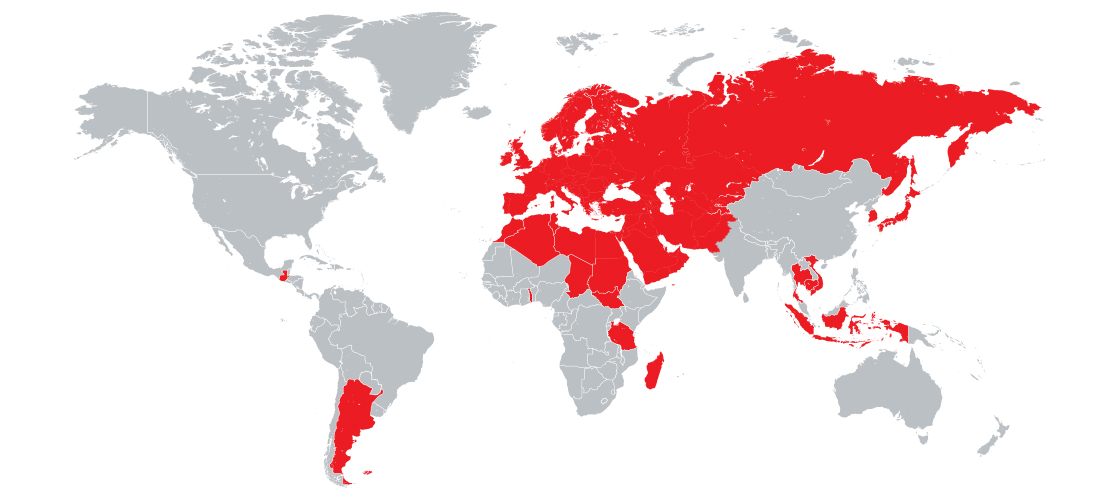

Onze klanten hebben veel vertrouwen in onze voertuigen en ons bedrijf. Van Ulm tot Seoul, in meer dan 55 landen, ontvangen onze potentiële en bestaande klanten de persoonlijke aandacht die zij nodig hebben van ons uitgebreide sales, aftersales en service netwerk.

Ons netwerk van lokale experts en key accounts teams werkt samen voorbij de landsgrenzen, en zorgt voor onze klanten vanaf hun initiële aankoop tot het onderhoud van hun vloot tijdens operaties.