K.SWAU CC 45

THE FIRST AND ONLY 45 ft. COIL SWAP BODY

K.SWAU CC 45

THE FIRST AND ONLY 45 ft. COIL SWAP BODY

The innovative character of Kässbohrer 45 ft. Coil swap body K.SWAU.CC / 45 is that it is the first ever and only 45ft coil swap vehicle and the only one certified 45 ft. swap vehicle for intermodal coil transport all made possible by its innovative design.

FEATURES

Kässbohrer 45ft Coil Swap K.SWAU.CC/45 is the only certified coil swap body with certificate UIC 592/IRS 50592. During UIC 592/IRS 50592 grab lifting tests, Kässbohrer concluded the safest grab lifting operations are performed when the chassis dimensions allow for at least 100 mm distance between the grab lifting grooves and the wagon solebar. Result of Kässbohrer’s meticulous design process, the resulting technical specification for safer grab lifting operation is now mandatory under IRS 50596-5 that will apply to all swap bodies under UIC 592 / IRS 50592..

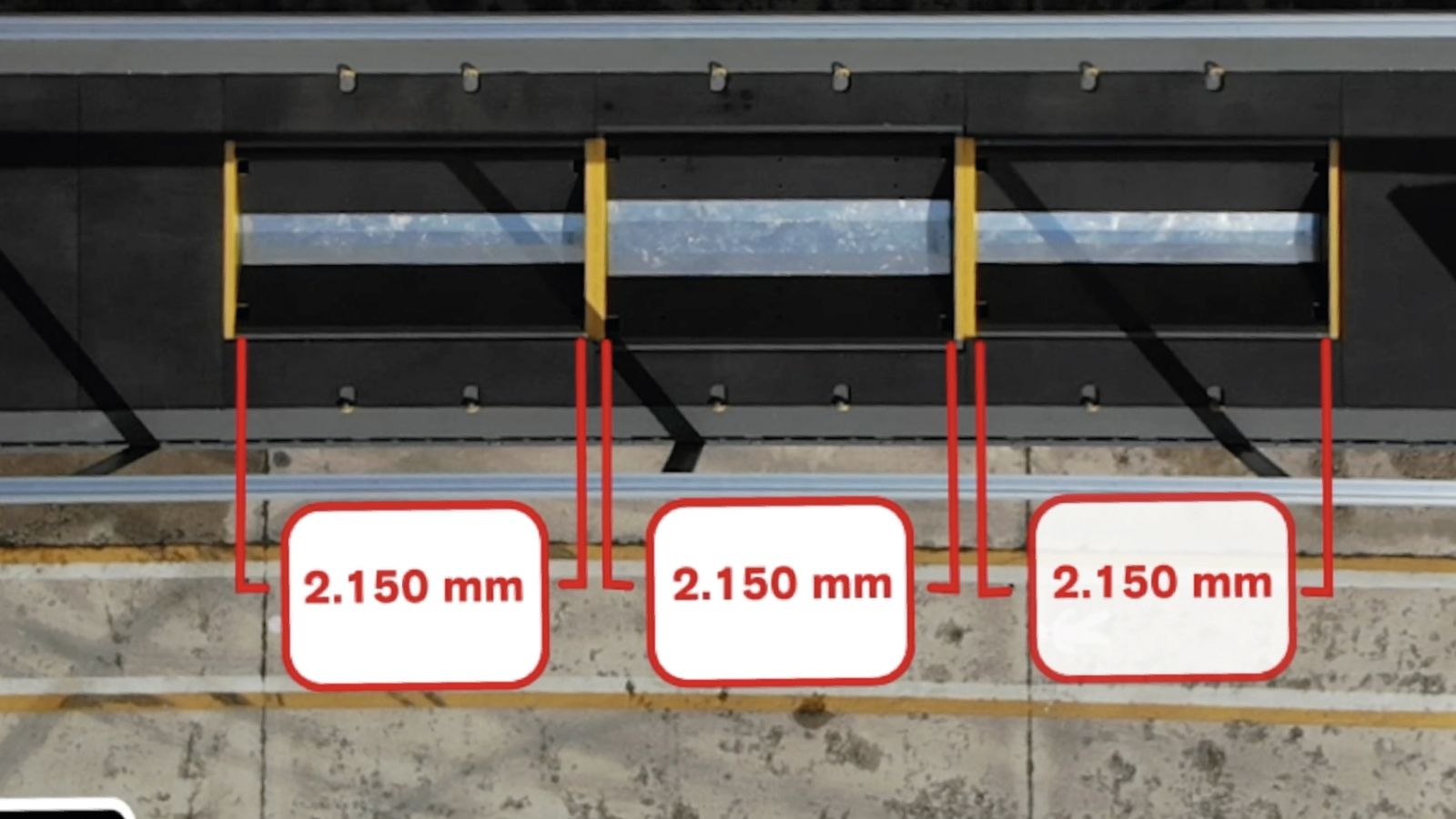

Offered with 3 units of 2.150 mm coil well, this feature enables to carry coil wells up to 30 tons with different tonnage and number of rolls. The coil well with 3 units allows the coils to be placed in different locations within the coil well and ensures the ideal load distribution and increases the load safety to the next level. (1x30 ton, 2x15 ton, 3x10 ton). It has 2-4 tons more payload capacity than the other coil transportation modes.

Offered with 6 x 2 lashing rings each with 5,2 ton capacity and 6 x 2 pillar pockets, it provides maximum load safety during coil transportation. It provides maximum load safety in general cargo trans- portation with 49 x 2 lashing rings each with 2,5 ton and 14 2 lashing rings each with 2,5 ton on the rave. Even with its aluminum coil well covers, its resistance to 7.2-ton forklift axle load provides operational flexibility in general cargo transportation as well as coil well transportation. In this way, K.SWAU CC 45 provides maximum load safety in both coil well and general cargo transportation.

In cases where the length/diameter ratio of the loaded coil roll is 0.66 and above, it has a coil well design that allows loading without the need for extra load safety support for the pillars. With this design, there is no need for a pillar placement that will prolong the loading operation.

.png?auto=format)

The 24 steel stripped sheet enforced sliding side curtain provides Code XL compliance without side planks. With- out side structure, maximum speed and efficiency is ensured in the loading / unloading operations of general cargo loads with only curtain opening / closing operation.

The only swap bodies with KTL and metallization applica- tions are the result of Kässbohrer’s engineering. The points of the Swap Body that are in contact with the container chassis and wagon during container chassis and wagon loading are protected by the metalization application against wears and tears that can be exposed under harsh operating conditions. The rest of the chassis is also protected with KTL coating against rust perforation that Swap Body could encounter under the difficult climate and road conditions.